-

Sort by

- All

- News

- Recruitment

- Customer Testimonial

February 2024

Milling Operator (Day & Night Shift)

Job Profile – Milling Operator (Day & Night Shift) Click the link to view the Job Profile Job Title – CNC Machinist Job Description – Operating CNC milling machines to manufacture precision metal and plastic components to customer’s specifications Working as part of the production team your primary focus will be to… View Article

read moreFebruary 2024

MILLING SETTER OPERATORS (DAY & NIGHT SHIFT)

Job Profile – Milling Setter Operator (Day & Night Shift) – Click the link to view the Job Profile Job Title – CNC Machinist Job Description – Setting and operating CNC milling machines to manufacture precision metal and plastic components to customer’s specifications Working as part of the production team your primary… View Article

read more

January 2024

Maximum Precision 2023 Yearly Round Up

Maximum Precision is excited to showcase our 2023 annual round up! In 2023, Maximum experienced a year unlike any other. We dedicated ourselves to business growth through new machinery, additional premises and expanding our exceptional team. Our commitment and initiative drove us to consistently deliver the best service and quality to our valued customers. A… View Article

read more

September 2023

Maximum Passes ISO9001 Audit

At Maximum Precision, quality is non-negotiable. We are pleased to announce we have once again passed the ISO9001 audit with flying colours. We excel in our field because we understand that precision is not just the goal; it’s the commitment to excellence. We continue to demonstrate our unwavering dedication to quality by once again passing… View Article

read more

August 2023

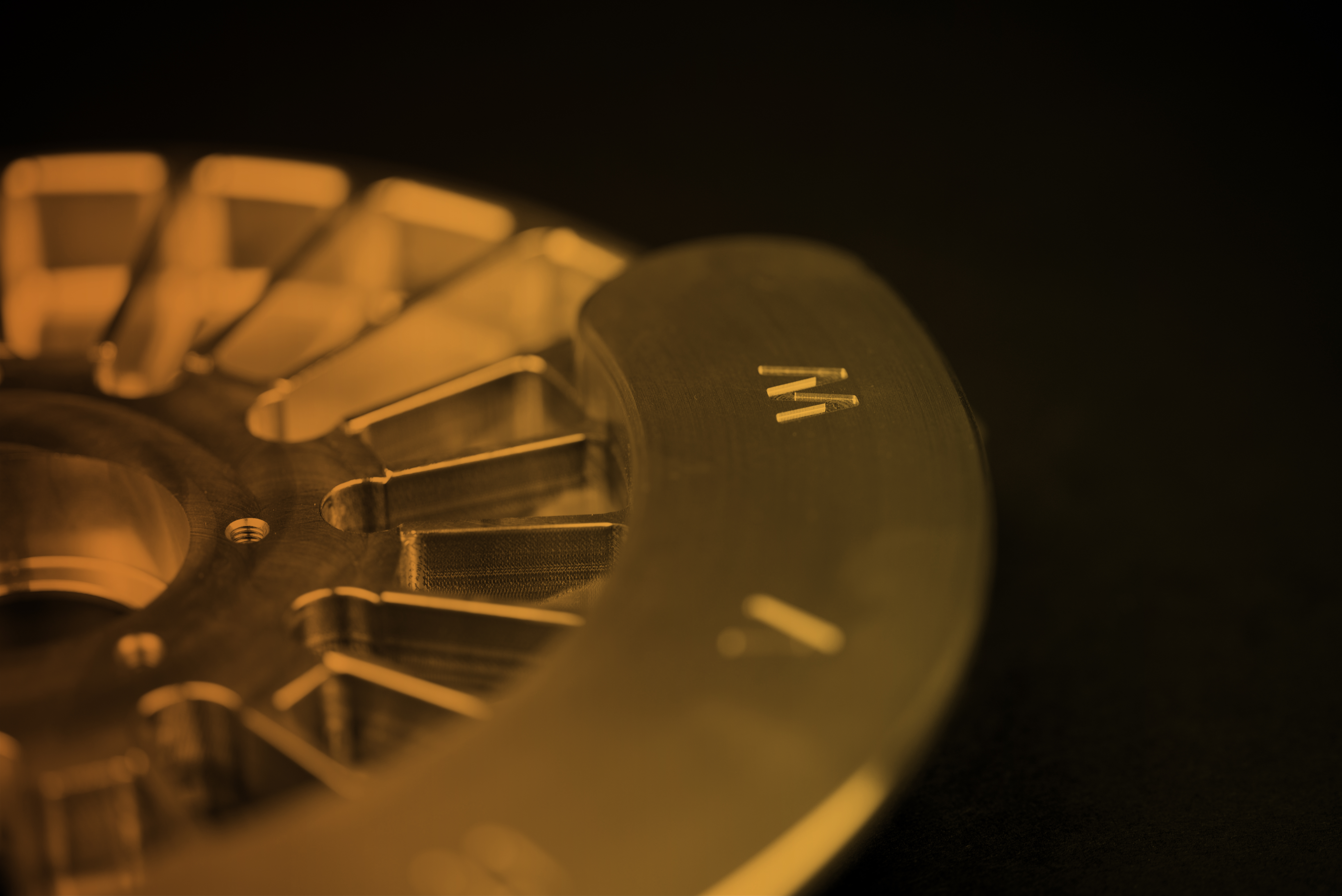

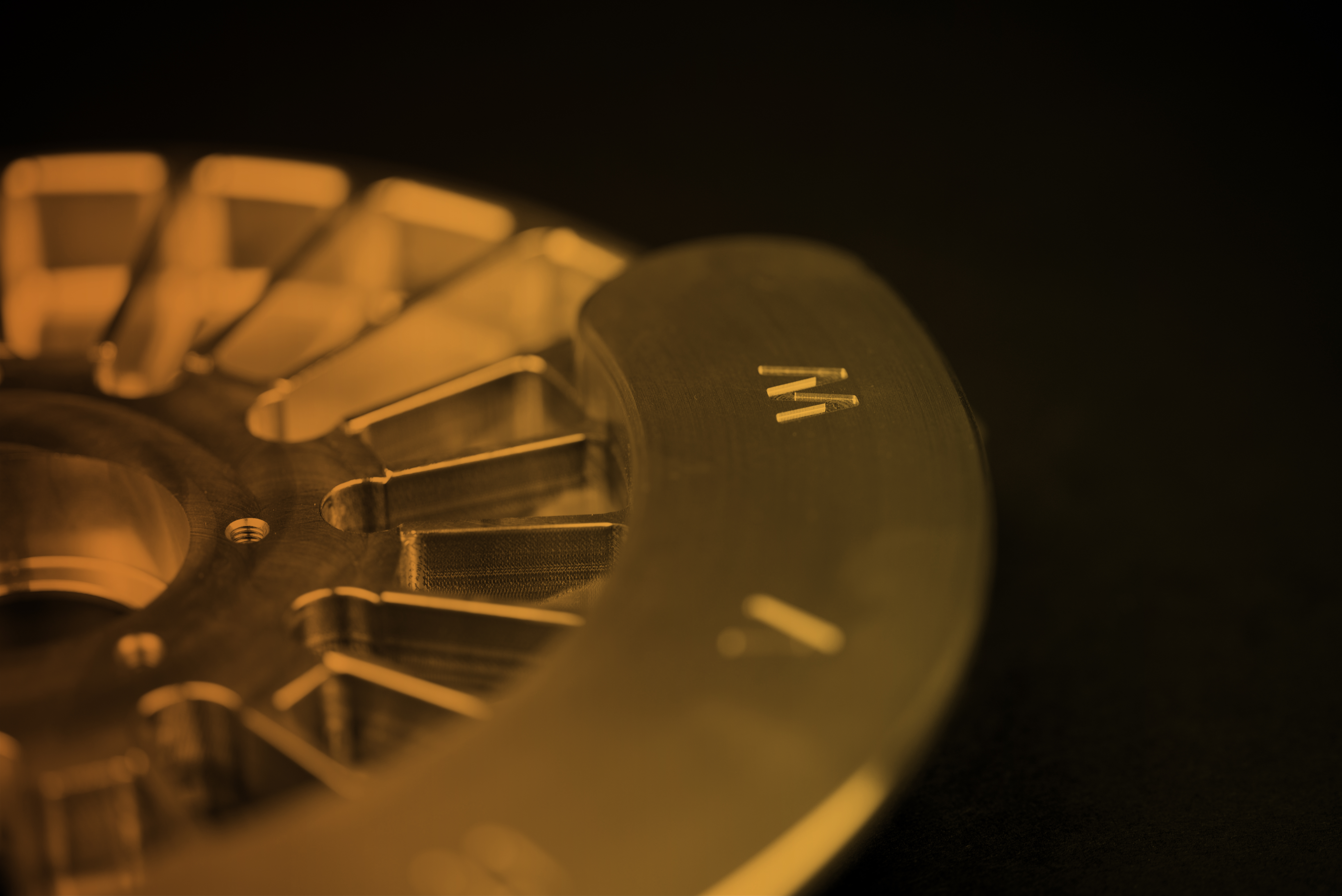

New Investment in a Second Matsuura H-PLUS 300

Maximum Precision has recently taken delivery of another machine! Having has such great success with our first machine, we have invested in a second Matsuura H-PLUS 300. We are so pleased to be adding another Matsuura to our machining arsenal. By embracing the reliable, robust nature of the machine’s capabilities, we are able to produce… View Article

read more

July 2023

MAXIMUM INVESTS IN NEW PREMISES

We are pleased to announce, Maximum Precision has invested in a new premises! This exciting development reflects in our commitment to growth and innovation. The decision to invest in a new premises comes as no surprise to those familiar with Maximum Precisions unwavering dedication to delivering a high-quality service! Adding another building to our ever-growing… View Article

read more

July 2023

Machining Prototypes before Development – 3 Reasons Why it Benefits Your Business

In the realm of product development, the importance of prototyping cannot be overstated. Machining prototypes offers many advantages for you and your business. Read our 3 key gains to machine prototypes before development. Verification of Design Machining allows you to create a physical representation of your product design. Having the ability to hold and examine… View Article

read more

April 2023

UK Precision Engineering

It’s a well-known fact it can be cheaper to obtain your parts from machinists overseas. Cheaper raw material and significantly cheaper labour costs contributes to keeping costs down. Whilst your margins may be wider and profits increased, the chain of communication is often broken, resulting in quality issues for you and your customer. Can UK… View Article

read more

February 2023

Three reasons why you should review your current CNC supplier

If you’re encountering problems with your current CNC machinist and they haven’t been meeting your current demands, it may be time for a change. Here are 3 core factors you should regularly review in relation to your CNC machining supplier. Poor Quality Your supplier has very little quality control resulting in continually receiving poor… View Article

read more

January 2023

Happy New Year from Maximum Precision!

Everyone here at Maximum Precision, wishes you a Happy New Year! After the Christmas haze, eating too much and not being entirely sure what day it is, we are pleased to be back. We have plenty of exciting things coming up in 2023 and were looking forward to sharing them with you! If you are… View Article

read more

December 2022

Maximum Precision 2022 Yearly Round Up

Maximum Precision is pleased to present our 2022 yearly round up! Another year, done and dusted and its nearly time to put down our tools and prepare for an even more exciting 2023. 2022 has been a year like no other, Maximum has continued to invest in the growth of the business, with new machinery… View Article

read more

September 2022

JOIN THE MAXIMUM PRECISION TEAM

Maximum Precision is always on the lookout for talented people to join our team! We pride ourselves on delivering outstanding results to our customers and we’re always striving for excellence. We believe in co-working and honest partnerships which is why we can build strong, long-lasting relationship. We endeavour for a connected company culture, where the… View Article

read more

May 2022

MAXIMUM INVESTS IN MATSUURA MX-330 PC10

It was the first delivery day of the year here at Maximum Precision yesterday. We are proud to announce we have invested in the Matsuura MX-330 PC10. A great day to add further capabilities to the ever-growing workshop. Our newest machine boasts a 10-pallet configuration, 5-axis production, and a large tooling capacity. Moreover, the MX-330… View Article

read more

December 2021

Maximum Precision’s Yearly Round Up

In a world where masks and lateral flow tests have become part of our everyday lives and change management is the order of the day, Maximum Precision have adapted to this situation with focus, commitment and drive and certainly made the most of the past 12-months. Here we highlight our yearly round up! Our investment… View Article

read more

October 2021

MAXIMUM INVESTS IN SLIDING HEAD LATHES

Today Maximum Precision has welcomed two new Star sliding head lathes to the new unit! Yes, we’ve began filling the new unit already. Our machining capabilities have expanded once more, with the Star SB-20R and Star SR-20Jll joining the team. Both new machines offer Maximum, consistency, accuracy, and versatility. The functionality of these sliding head… View Article

read more

September 2021

MAXIMUM SECURES NEW PREMISES

Maximum Precision is proud to announce its continued growth due to unrelenting business demand and, as a result, we have secured another premises for the next stage of our expansion. We have added another building to our existing facilities to enable us to serve our customers better and expand our capabilities. More space allows for… View Article

read more

September 2021

MAXIMUM PRECISION RACING TO RAISE MONEY

Maximum Precision once again braved the slopes of the Newmarket Soapbox Derby! This year, we raced to raise money! Our brave volunteers this year, Richard, Harry, Dawie and Josh, were excited to take on the race and raise as much money as possible. The iconic race took place on August Bank Holiday, dressed as characters… View Article

read more

July 2021

Soapbox Derby 2021!

Maximum Precision will once again be racing in the next Newmarket Soapbox Derby 2021! Having joined in on the fun in 2019, we decided to do it all again. This year we are racing to raise money! This year, we will be raising money for the East Anglian Air Ambulance. East Anglian Air Ambulance exists… View Article

read more

June 2021

MPL INVESTS IN DOOSAN LYNX 2100

It is delivery day, again! Maximum Precision welcomes to the ranks, the Doosan Lynx 2100 LYSA. The turning department has finally gained another machine. The Doosan Lynx has been newly designed and is as powerful as ever. The 2-axis, horizontal turning centre may be compact, but it is big in productivity. This latest investment at… View Article

read more

February 2021

MAXIMUM PRECISION INVESTS IN MATSUURA H.PLUS-300

It is delivery day here at Maximum Precision and joining the ranks is the Matsuura H.PLUS-300 CNC horizontal machining centre. With its 15-pallet configuration, high speeds and large tooling capacity, the H.PLUS-300 sets the bar high for reliable unmanned overnight running. At MPL we are continually investing in our people and technology whilst always staying… View Article

read moreDecember 2020

STAYING COVID-19 SECURE IN 2020

We confirm we have complied with the government’s guidance on managing the risk of COVID-19. Follow the link below to find out more. MPL Staying COVID-19 Secure

read moreNovember 2020

A MAXIMUM PRECISION COVID-19 UPDATE

The global implications due to coronavirus have obviously been significant and has led to huge change within industry and commerce for everyone. Throughout the pandemic, Maximum Precision Limited have undertaken several measures to ensure we can continue to provide a first-class service to its customers and maintain excellent relationships with customers and suppliers alike. As… View Article

read more

July 2020

ISO9001 – Making excellence a habit

Quality Management is a key driver for any business wanting to ensure customer satisfaction and high quality with manufacturing. The ISO9001 standard provides a framework to companies that want to consistently meet and exceed customer requirements and is based on a number of quality management principles. These principles are extensive and range from a strong… View Article

read more

April 2020

OUT WITH THE OLD, IN WITH THE NEW

As the saying goes; out with the old, in with the new! There have been some exciting changes and new additions here at Maximum Precision that we are thrilled to share with you. We have made the difficult decision to part with one of our older, trusted milling machines. When you have a piece of… View Article

read more

March 2020

MAXIMUM PRECISION – WORKING FROM HOME

The Prime Minister has placed the U.K on lockdown to contain the spread of the Coronavirus; like many of you following the government guidelines Maximum Precision office colleagues are working from home. Working from home can be quite the adjustment, especially if you’re used to working in a busy office environment! We’ve asked a few… View Article

read moreMarch 2020

A MESSAGE FROM MAXIMUM PRECISION – COVID-19

A message from Maximum Precision During these uncertain times we want to update you with the steps that we are taking here at Maximum Precision to ensure that we do all we can to protect the well-being of all of our employees, colleagues and customers and to safeguard the wider community whilst ensuring continuity… View Article

read more

February 2020

Managing for Daily Improvement

“The flawed notion that progress happens in leaps and bounds is an organisational curse. Real progress starts and ends with teams committed to taking one step at a time together.”

read more

January 2020

Maximum Welcomes Business Development Manager!

As we started the new year, we also welcomed the latest member of the Maximum Precision team. Gary Payne joins us as business development manager and his core focus will be developing relationships with new customers to support our next phase of growth. Exciting times are ahead for the business and we wish Gary every… View Article

read more

January 2020

Made in Central and East England Awards 2020

The Made in Central and East England Awards have officially announced the shortlisted candidates for this year’s awards ceremony. Maximum Precision has been shortlisted for the category ‘Manufacturer of the Year’ (below £25m turnover)! It is an amazing achievement to be placed among the best manufacturing companies within the region and to be recognised by… View Article

read more

December 2019

Maximum does Advent Calendar Collection!

This year the Maximum team took part in a advent calendar collection to donate to the Ely Food Bank, just in time for the Christmas period! Maximum have collected 24 advent calendars and we will be handing them over to the food bank this week. A message from the local food bank.. “We are currently… View Article

read more

September 2019

Ely Standard Business Awards? We’re finalists!

Friday 20th September, Ely Cathedral hosted the Ely Standard Business Awards! A night dedicated to celebrating local businesses hard work and passion for their industries. All of us coming together to rejoice over another successful year. We were lucky enough to be finalists for the Employer of the Year category. We were alongside some of… View Article

read more

August 2019

Newmarket Soapbox Derby 2019!

Newmarket, famously known for being the headquarters for all things horse racing. However, the Suffolk town now offers another race that doesn’t take place on the Rowley Mile or the July Course. The Newmarket Soapbox Derby! This year three brave members of team Maximum Precision buckled up and entered the 700-meter, obstacle ridden, downhill descent… View Article

read more

June 2019

Cambridgeshire Fire and Rescue Service Award

We have been recognised by the Cambridgeshire Fire and Rescue service as an on-call employer! An award was presented by Ian Smith and Simon Newton. They came down for an afternoon visit, thanking our very own Patrick Whitton for his service. Patrick is released from duties here to attend incidents when called by the rescue… View Article

read more

May 2019

Efficiency in the Heart of the UK

According to the Office of National Statistics, in 2017 the value of UK manufacturers’ product sales was £380.7 billion; a 4.1% increase on the 2016 final total of £365.7 billion. When it comes to choosing a supplier, not everyone can afford to buy from British suppliers due to the price of raw materials, labour and… View Article

read more

April 2019

Bringing manufacturing back to the UK

The problem Outsourcing work to the Far East is commonplace in Britain today, due to cheaper than average machining costs. It’s a problem British Manufacturers have faced for quite some time, however quality and reliability can be quiet an issue. A long-term customer of ours ran into some trouble when an injection moulded part was… View Article

read more

April 2019

High-end manufacturer rejoices with exacting standards

Being known as an industry leader is quite the accomplishment; it speaks volumes about the manufacturing process, quality control and overall product that’s provided to customers. Known for having a clear and dependable vision, leading companies take pride in the product they make and will stop at nothing to bring the best product to market…. View Article

read more

January 2019

MAXIMUM PRECISION SHORTLISTED FOR MADE IN CENTRAL AND EAST ENGLAND AWARDS!

The Made In Central and East England Award nominations have come in and we are very pleased to announce that Maximum Precision has been shortlisted by Insider Media Limited. The category we’re up for is Manufacturer of the Year (below £25m turnover) and the whole business is thrilled to be nominated! The Made In Central… View Article

read more

January 2019

When Christmas Looms…Maximum Precision Saves the Day

Christmas break is something everyone in all industries looks forward too, a few days off relaxing with friends and family after another chaotic year. Those in manufacturing will be aware of the madness that ensues a few days, even weeks before the break is due. Last minute orders, suppliers closing earlier than everyone else and… View Article

read more

December 2018

MAXIMUM PRECISION INVESTS IN NEW VF2SS

To complement its existing capabilities, Maximum Precision has invested in the latest CNC Turning Centre with Driven Tooling. This machine, supplied by Mills CNC, gives us full Mill-Turn…

read more