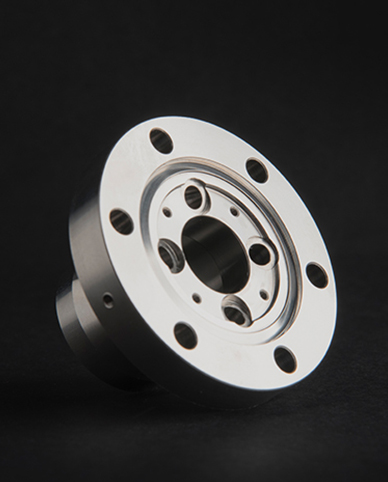

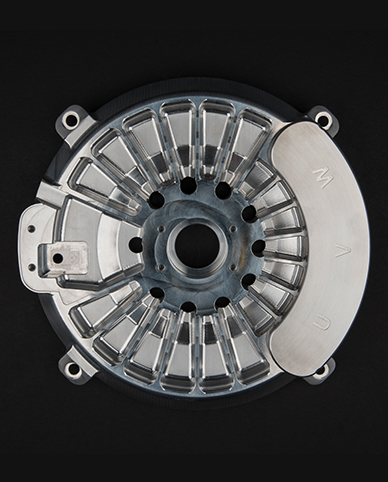

CNC Turning is a process based on rotating stock round bar against cutting tools to create cylindrical parts to tight tolerances. We use a variety of lathes with live tooling to produce complex parts including features such as grooves, flats, holes and threads machined on many different surfaces of the part. This approach means we can eliminate the multiple operations conventionally used to machine apart and complete it in just one!

We use the latest in conventional 2 axis, driven tooling and Sliding head machines that provide mill-turn capabilities ensuring we produce your components using the most efficient and cost-effective methods.

Keep Exploring

INVESTMENT IN THE LATEST CNC MACHINES ENSURES WE HAVE THE CAPABILITY TO MEET OUR CUSTOMERS REQUIREMENTS.